In our new report on characterization of surface properties of minerals, entitled Diffuse-Layer Surface Potentials of Colemanites Mined in Turkey and published in Physicochemical Problems of Minerals Processing, we examine the surface potentials of colemanites. The following is the abstract:

Colemanite crystal specimens were handpicked at Kestelek, Emet (Hisarcik, Espey), Bigadic mines in Turkey for characterization of their composition and surface potential. X-ray diffraction analysis revealed no differences in mineralogical makeup of the crystals, but elemental analysis indicated differences in the type of trace (<0.1 wt%) elements. Zeta potential measurements showed small differences in zeta potential values, with isoelectric points (iep) varying from about pH = 9.6 to pH = 10.2. However, no correlation was found between iep and the type of trace elements. Additionally, atomic force microscopy (AFM) was employed to measure the colloidal interactions between a silicon nitride (Si3N4) cantilever tip and colemanite crystal surfaces in 1 wt% colemanite-saturated aqueous solutions at three different pHs (8.4, 9.4 and 11). The Derjaguin-Landau-Verwey-Overbeek theory (DLVO) was applied to examine the AFM tip interactions with colemanite surfaces in an aqueous solution of colemanite saturated solutions. The results revealed attractive forces at pH = 8.4 and 9.4 and repulsive forces at pH = 11, confirming the location of an isoelectric point for colemanite specimens somewhere between pH = 9.5 and pH = 10.1. Theoretical analysis of the force curves using the DLVO theory allowed for assessment of both surface charge density and surface potential for colemanite specimens used in this study.

Surface Potential of Colemanites

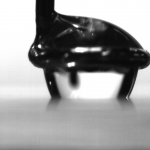

Droplet on Spherical Surfaces

In our new report on adhesion of liquids to solids, entitled Droplet Spreading and Adhesion on Spherical Surfaces and published in Langmuir, we analyze the effect of solid surface curvature on liquid droplet adhesion. The following is the abstract:

Adhesion of a liquid droplet to a solid surface is a result of solid surface interactions with surrounding fluids, affected by its wettability and morphology. Unfortunately, the direct measurements of adhesion forces are rarely reported in the scientific literature, especially for solids with curvatures. In this study, by using a high-sensitivity microelectronic mechanical balance which vertically deposits and then pulls liquid droplets, the spreading and adhesion forces for water and ethylene glycol droplets on spherical surfaces of polyethylene terephthalate (PET) with radii of curvature from 2 to 8 mm were recorded. Results show that surface curvature does not affect the advancing and most-stable contact angles but affects the extent of spreading and maximum adhesion forces. The solid surface curvature affects both surface tension and Laplace pressure forces at the spreading point, whereas it mainly affects the Laplace pressure force at the maximum adhesion point.

SI Volume 10 Issue 4/5

The 4-5 issue of 2022 includes the Invited Feature Article and seven Original Research papers on a broad variety of topics. Hope you will find research inspirations after reading the following papers:

Triboinformatics: machine learning algorithms and data topology methods for tribology; Md Syam Hasan, Michael Nosonovsky; 10(4-5), pp. 229–242

Synthesis and characterization of chitosan-based ‘comb-like’ zwitterionic surfactants; Jing Xu, Jing-jing Du, Xiao-hui Han, Bo Wang, Zhang Zhang; 10(4-5), pp. 243–251

Hydrothermal treatment of the silver-incorporated MAO coated Ti6Al7Nb alloy; Dilek Teker Aydogan, Faiz Muhaffel, Huseyin Cimenoglu; 10(4-5), pp. 252–262

Fabrication of Joule heating coating layers by way of flame spraying for membrane distillation; Arian Enayat, Mohtada Sadrzadeh, André McDonald; 10(4-5), pp. 263–277

Effect of laser texturing pattern on Ti6Al4V tribocorrosion in a physiological solution; Marjetka Conradi, Tadeja Kosec, Bojan Podgornik, Aleksandra Kocijan, Janez Kovač, Damjan Klobčar; 10(4-5), pp. 278–288

Structural and electrical properties of irradiated flexible ZnO/PVA nanocomposite films; Eslam Abdeltwab, Ali Atta; 10(4-5), pp. 289–297

Triallyl ammonium amphiphiles: self-assembly and complexation with bovine serum albumin; Denis M Kuznetsov, Darya A Kuznetsova, Dinar R Gabdrakhmanov, Svetlana S Lukashenko, Yevgeniy N Nikitin, Lucia Ya Zakharova; 10(4-5), pp. 298–311

Novel composites made of natural and waste rubber loaded with lead nanoparticles for gamma radiation shielding; Ahmed M El-Khatib, Ahmed S Doma, Asmaa E Abu-Rayan, Nor S Aly, Mahmoud I Abbas; 10(4-5), pp. 312–328

Beside papers that have already been published in the first three issues of 2022, there are several Ahead of Print reports available on the journal website.

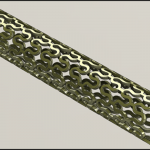

Zn Biomaterials Processing

Zn-based alloys are potential candidates for bioabsorbable metallic devices due to their ideal corrosion rates and biocompatibility. However, strain softening and rate sensitivity in tensile testing remain as challenges for their use in load bearing applications. In our new studies Flow Stress Stabilization of Zn-Cu-Mn-Mg Alloys using Thermomechanical Processing, published in Materials Characterization, three different Zn-xCu-yMn-0.05Mg (x = 0.5, 1.0 wt.%, y = 0.4, 0.6 wt.%) alloys were formulated and their microstructure and tensile properties in the cold rolled condition were characterized. Additionally, the effect of short-time annealing at 320 ℃ on the strain softening and strain rate sensitivity of alloys were studied. The results indicate that dissolution of secondary phases and grain coarsening lead to the elimination of strain softening and rate sensitivity. The evolution of microstructure during the room-temperature tensile testing indicates that dynamic recrystallization is responsible for strain softening and can be eliminated by tuning the fraction of secondary phases and underlying grain size. The formulated alloys are not susceptible to natural aging and show good thermal stability during aging up to 200 ℃ for 60 h due to the pinning effect of MnZn13 precipitates on the grain boundaries.

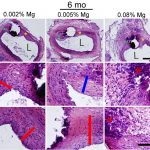

Biocompatibility of Zn-Ag Alloys

Our internal collaborators from Biomedical Engineering, together with collaborators from Mayo Clinic, were instrumental in preparation and publishing of a new report on biocompatibility of Zn-based materials. The paper entitled Improved Biocompatibility of Zn-Ag-based Stent Materials by Thermal Processing was published in Acta Biomaterialia.

The metallurgical engineering of bioresorbable zinc (Zn)-based medical alloys would greatly benefit from clarification of the relationships between material properties and biological responses. Here we investigate the biocompatibility of three novel Zn-based silver (Ag)-containing alloys, ranging from binary to quinary alloy systems. Selected binary and quinary Zn-Ag-based alloys underwent solution treatment (ST) to increase the solubility of Ag-rich phases within the Zn bulk matrix, yielding two different microstructures (one without ST and a different one with ST) with the same elemental composition. This experimental design was intended to clarify the relationship between elemental profile/microstructure and biocompatibility for the Zn-Ag system. We found that the quinary alloy system (Zn-4Ag-0.8Cu-0.6Mn-0.15Zr) performed significantly better, in terms of histomorphometry, than any alloy system we have evaluated to date. Furthermore, when solution treated to increase strength and ductility and reduce the fraction of Ag-rich phases, the quinary alloy biocompatibility further improved. We conclude that Zn-Ag alloys can be engineered through alloying to substantially reduce neointimal growth. The positive effect on neointimal growth can be further enhanced by dissolving the AgZn3 precipitates in the Zn matrix. These findings demonstrate that neointimal-forming cells can be regulated by elemental additions and microstructural changes in degradable Zn-based implant materials.

New PhD Candidate

Mr. Matthew Graham has joined our research team as a PhD Candidate in Fall 2021. He is a distance graduate student whose interests are in surfaces and surface coatings. Matthew earned his MS degree in Polymer Science and Engineering from Lehigh University with a thesis that involved the estimation of the surface energy of electroplated chromium. He intends to continue his research journey in the field of coating adhesion and possible benefits of surface energy analysis.

New MS Candidate

Henry Summers has joined our research team in 2021 as an undergraduate researcher. Why he continues his B.S. degree program, he also started his accelerated Master of Science degree program.

His research effort is concentrated towards characterization of zinc alloys at different processing stages of cardiovascular stent manufacturing.

Morteza Graduates

Congratulations to Dr. Morteza Ardakani for defending his PhD dissertation and graduating in Spring 2022.!

Morteza dissertation is entitled Engineering Mechanically-Stable Zinc-based Alloys for Medical Implants, and the following is the abstract:

Zinc-based alloys have been introduced as candidate absorbable materials for biomedical implants due to their biocompatibility and application-appropriate corrosion rate. However, poor mechanical strength and ductility, as well as susceptibility to creep and fatigue, restrict their usage in load-bearing stenting applications. Many studies have been conducted that attempt to overcome these limitations by using a combination of alloying and microstructural refinement; these have resulted in some successes in increasing their strength. Nevertheless, room temperature aging, strain softening, and strain rate sensitivity within these alloys remain unresolved. These properties can negatively affect the elongation to failure, as well as the creep and fatigue resistance of the zinc-based alloys.

This Ph.D. research identifies the mechanisms of the mechanical instabilities that are inherent to these alloys, including natural (room temperature) aging, strain softening during deformation, and a sensitivity to deformation rate (i.e., strain rate sensitivity). Natural aging of a zinc-magnesium binary alloy was studied and a successful strategy to reduce the effect was identified by introduction of a third alloying element to the zinc solid solution. This method was used for the first time in zinc-based alloys to eliminate natural aging. Strain softening and strain rate sensitivity of cold-rolled zinc-based alloys were reduced through heat treatments that act to modify the grain size and the fraction of the secondary phase. Specifically, short-time annealing alters the microstructure in a way such that the predominant deformation mechanism shifts from dynamic recovery and recrystallization to homogenized dislocation slipping. This is due to the reduction of the deformation gradient resulting from the reintroduction of the alloying elements and grain growth after annealing. Finally, cross rolling and hot rolling were hypothesized and studied as strategies that would serve to promote the development of a lower-energy substructure and to reduce the driving force for following dynamic recrystallization.

The presented fundamental study introduces a new approach for stabilizing the microstructure and mechanical properties of zinc-based alloys by using a specific group of alloying elements followed by performing post-deformation annealing. The results provide promising progress in the use of these alloys in load-bearing applications as biodegradable metallic materials.

SI Volume 10 Issue 3

The third issue of 2022 includes the Invited Feature Article and five Original Research papers on a broad variety of topics. Hope you will find research inspirations after reading the following papers:

Evolution of antibacterial and antibiofouling properties of sharkskin-patterned surfaces; Sabra Rostami, Bora Garipcan; 10(3), pp. 165–190

Tuning water adhesion of superhydrophobic surface by way of facile laser–chemical hybrid process; Qinghua Wang, Huixin Wang; 10(3), pp. 191–199

Preparation of copper nanowires and thermal oxidation behaviour in dry oxygen; Xiangming Zeng, Peng Pan, Hao Qi, Zuming He, Jiangbin Su; 10(3), pp. 200–208

Yolk–shell structured sulfur composite cathode for high performance lithium–sulfur battery; Kaikai Tang, Jun Xiao, Mengqi Long, Jun Chen, Hong Gao, Hao Liu; 10(3), pp. 209–216

Study of the structure and properties of a high-entropy ceramic composite material; Peter O Rusinov, Zhesfina M. Blednova; 10(3), pp. 217–226

Beside papers that have already been published in the first three issues of 2022, there are several Ahead of Print reports available on the journal website.

SI Volume 10 Issue 2

The second issue of 2022 includes the Invited Feature Article and five Original Research papers on a broad variety of topics. Hope you will find research inspirations after reading the following papers:

Progress in fabrication and applications of micro/nanostructured superhydrophobic surfaces; Qing Wang, Shuangshuang Xu, Xiaoting Xing, Ning Wang; 10(2), pp. 89–110

Highly conductive polyester fabrics fabricated by graphene oxide printing and hot-pressing; Jiliang Cao, Xinyi Guan, Yan Wang, Licong Xu; 10(2), pp. 111–118

Enhanced electrochemical performance of Li-rich cathode material for lithium-ion batteries; Jun Xiao, Xiao Li, Kaikai Tang, Mengqi Long, Jun Chen, Dandan Wang, Hong Gao, Hao Liu; 10(2), pp. 119–127

Plasma-assisted fabrication of hydrophobic siloxane based sol–gel-coated coir fibres; K M Praveen, Gregor Primc, Barbara Simončič, Marija Gorjanc, Isabelle Pillin, Bastien Seantier, Antoine Kervoelen, Alenka Vesel, Nandakumar Kalarikkal, Miran Mozetič, Yves Grohens, Sabu Thomas; 10(2), pp. 128–139

Characteristics of silver-containing titanium-based coating after thermal oxidation; Dogukan Cetiner, Nevin Gul Karaguler, Huseyin Cimenoglu, Erdem Atar; 10(2), pp. 140–149

Impact of nano-titania and ultrasonic irradiation on the physical properties of polymer blend electrolytes; Jayanthi Santhana Krishnan, Sundaresan Balakrishnan; 10(2), pp. 150–162

Beside papers that have already been published in the first and second issues, there are several Ahead of Print reports available on the journal website.